Description

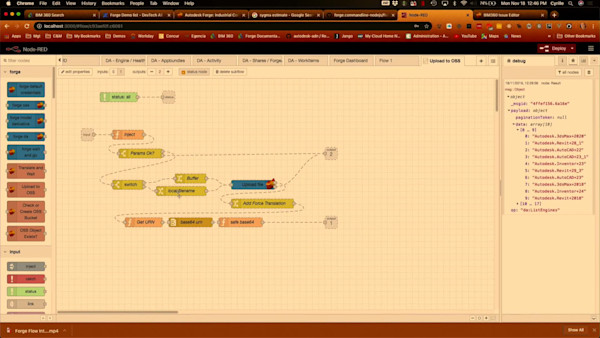

When planning a factory, many trades, project participants, and disciplines are involved. This presentation will show you an end-to-end digital process called the integrated factory model (IFM). The coordination of all project-relevant data is the basis of an end-to-end digital process and is largely responsible for the success of a project. A simple 3D construction space model gives each project participant their workspace. There, for example, the layout planner carries out process simulation and line planning with the Factory Design Utilities software. Due to the adjacent construction spaces, collisions with other layouts or the building equipment can be detected and eliminated at a very early stage. All data is continuously merged, checked, and adjusted in an overall coordination model in BIM 360 software.

Key Learnings

- Learn about integrated factory modeling use cases.

- Learn about the interaction between layout planning and AEC.

- Learn about the handling of large amounts of data in a layout.

- Learn about the cloud-based collaboration of all project participants.

Downloads

Tags

Product | |

Topics |

People who like this class also liked

Instructional Demo

BIM Workflows for the Structural Engineer: Design to Fabrication

Roundtable

Digital Twin for Building Owners

Industry Talk