Beschreibung

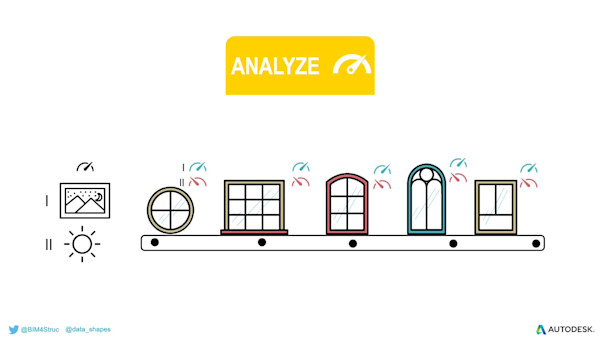

Housing has always been the largest sector of the U.S. economy. With increasing competition among architecture firms, designers need to figure out the most efficient options for their designs. Generative design that relies on the principles “generate, evaluate, and evolve” can help designers achieve seemingly limitless options within a short period—a task that is impossible for humans alone. In this class we’ll discuss the impact of generative design, using Dynamo scripts for multifamily residential design. Find out how you can use Dynamo scripts to drive efficiency in ways that benefit your architecture firm.

Wichtige Erkenntnisse

- Discover workflows in Dynamo for producing efficient multifamily design options

- Learn how to implement similar automation processes to minimize downtime

- Learn how to apply multifamily conceptualization in other sectors like hospitality, health care, and more

- Discover innovative design solutions for custom site conditions

Downloads

Tags

Produkt | |

Branchen | |

Themen |

Leute, die diesen Kurs mögen, mochten auch

Instructional Demo

Generative Design in Revit for Workspace Layout

Industry Talk

Using Generative Design in Construction Applications

Instructional Demo